More selectivity – more accuracy!

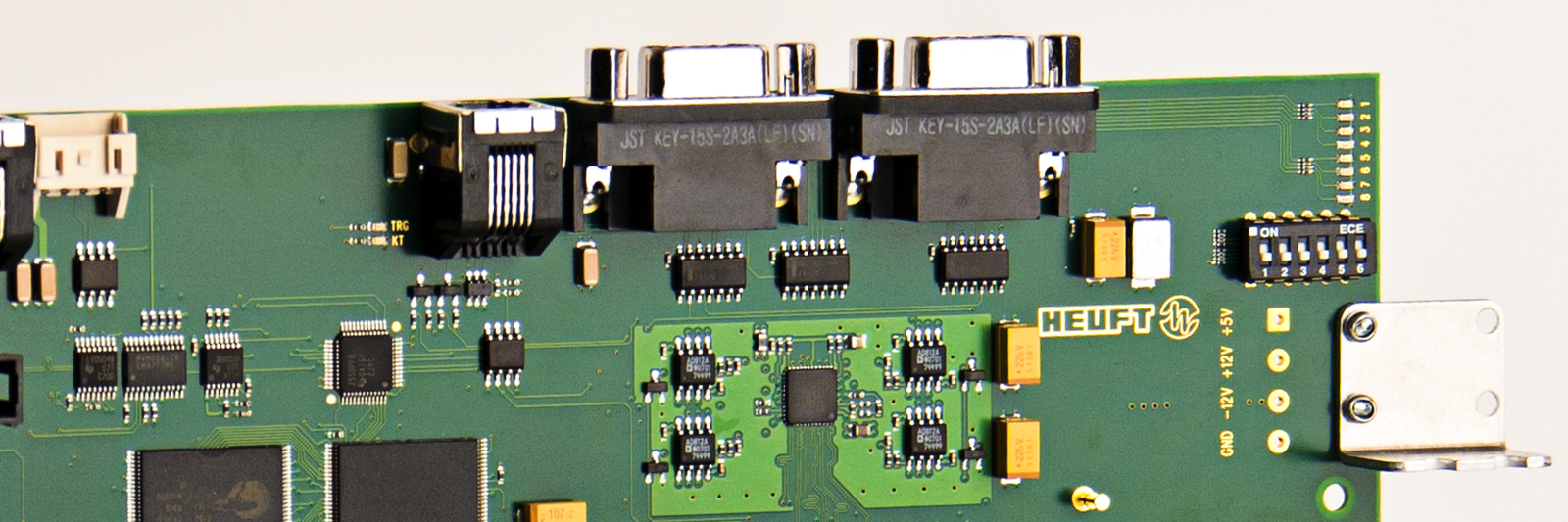

The HEUFT reflexx² real-time image processing system with learning ability is a standard feature of the new HEUFT SPECTRUM II devices. This has two positive effects with regard to the precision during the specific detection and rejection of faulty products.

Is it good? Is it faulty? As the decision-maker on site the verdict regarding the detected object rests with me! I can make up my own mind because nobody knows my quality requirements as well as I do. I would not even have noticed the tiny scratch on the bottle wall with my naked eye. It is good that the image processing system is five times more precise. In addition it compares the fault with other objects and provides a first evaluation independently. It is now up to me: should I teach in the marked scratch as a faulty object? Or as a good object after all? I can make the choice by simply tapping the touchscreen with my finger. The system now knows: it is not a real defect but only an uncritical fault. It threatens neither the safety and quality of my product nor the appearance of the packaging at the point of sale. Bottles with such properties will no longer be rejected with immediate effect.

Specific classification – individual teaching in

Therefore the HEUFT reflexx² achieves considerably more than the specific identification of all types of objects. The new real-time image processing system also classifies them using up to 50 different characteristics such as size or texture and carries out an individual teaching in process. I am able to sustainably characterise irregularities with it such as hairline scratches, slight scuffing, mould seams, embossing, orientation marks or drops of water on the outer wall as good. On the other hand I simply teach in serious threats to product safety and everything which does not satisfy my specific quality criteria as faulty objects. Consequently containers with cracks and chips on the finish and sidewalls, foreign objects on the inside and other critical defects are always removed from the production line.

But that is not all: a special reject rate control even makes it possible for me to react flexibly and allow bottles with harmless, purely aesthetic faults, such as severe scuffing, to be rejected only if the production situation actually permits it.

Classifying and teaching in function with a high degree of reliability, among other things, because the processor speed of the real-time image processing has quadrupled compared to the previous version. As a result systems with the HEUFT reflexx² provide considerably more selectivity when carrying out a quality inspection because they only reject that which has to be rejected. Therefore I can be sure that no critical containers are supplied which endanger the health of the consumer and the reputation of our brand. Furthermore I do not need to worry about uncritical containers being removed unnecessarily from the production flow. Because this would mean a threat to efficiency and productivity.

Precise monitoring – accurate rejecting

The proportion of good containers rejected by mistake is reduced even further in combination with the new HEUFT SPECTRUM II device platform. Because it provides considerably more computing power and therefore increased precision during the continuous tracking of the containers in real time. The actual position of each individual bottle can now be accurately determined up to 0.5 millimetres. This increases the accuracy during the rejection process. Consequently the container which the HEUFT reflexx² has identified as faulty on the basis of my specific quality requirements is sorted out precisely even along high-speed lines.