Empty bottle inspection

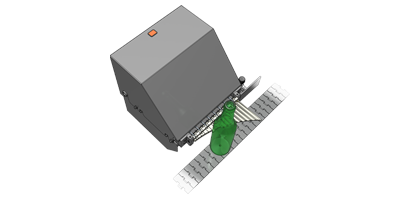

HEUFT InLine II IR

Your entry to the complete inspection of empty bottles on a HEUFT level.

Genuine high-tech for all: the long-standing benchmark for a continuous empty bottle inspection on only one square metre of floor space is now available based on the HEUFT SPECTRUM II. The modular HEUFT InLine II IR achieves an unprecedented level of automation, detection, manipulation and operational reliability and is ideal for craft brewers, wine bottlers as well as other SMEs who have limited space available and high quality standards. The compact system combines a proven design and sophisticated detection technologies with the performance and self-explanatory user guidance of the new generation.

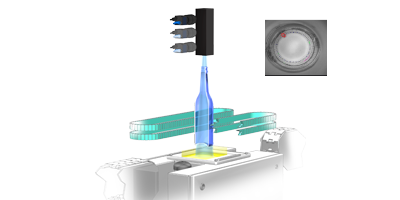

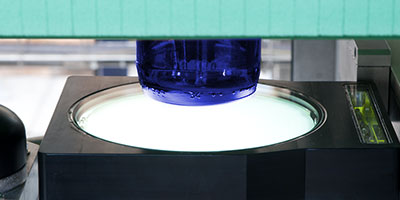

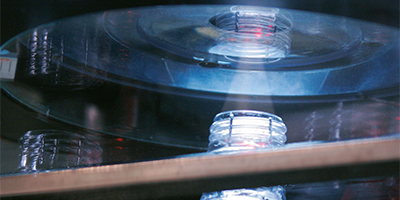

Optical base inspection

Covering everything: a continuous complete inspection of the whole base.

Film, cigarette ends, insects but also glass splinters and cracks: the HEUFT InLine II IR carries out an optical complete inspection of the bottle base in order to detect foreign objects and defects reliably. An LED illumination without reflections or shadows and specially positioned high-performance cameras even make transparent and reflecting faults visible. The HEUFT reflexx² image processing system combines and analyses the detection pictures in real time and makes a specific teach-in possible. Serious defects and foreign objects on the base of the bottles to be filled are therefore detected in good time and clearly distinguished from harmless aesthetic blemishes.

Fullscreen

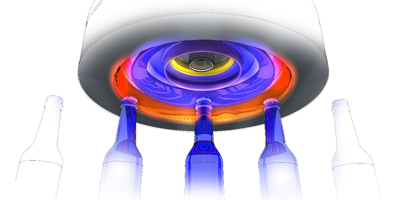

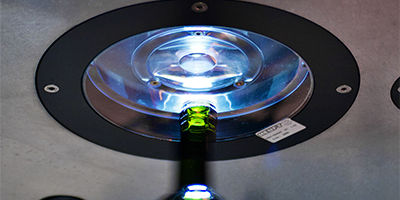

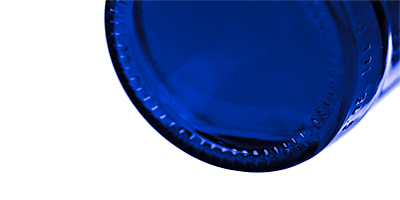

Extensive finish inspection

Finding finish faults: safety around the bottle opening.

Defects, cracks, rust rings, contamination and chips on the bottle finish: the HEUFT InLine II IR carries out an optical inspection of the complete finish and underchip area of each individual empty bottle in order to identify such faults reliably. The range of functions and the detection accuracy when examining the delicate area around the bottle opening can even be further extended by means of optional add-on modules (see below). Thus the compact device meets all the safety and quality requirements.

Fullscreen

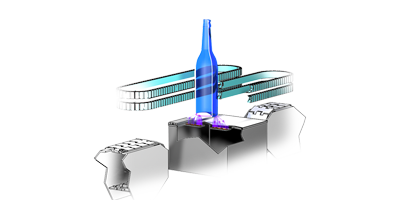

Continuous sidewall inspection

Inspecting all around: no blind spots.

Contamination, defects, cracks or inclusions: anyone wishing to detect such quality flaws reliably cannot afford to do without an all-around inspection. After all the sidewalls of the empty bottles should be covered completely. This is ensured by a harmonious LED illumination which prevents shadows and reflections in the detection pictures on the one hand. Thus the inspection of the complete bottle volume is already achieved in low speed ranges when there is a sufficient gap between the containers with the standard device which is only one metre long. Additional optical modules for a 360° sidewall inspection (see below) can be integrated in the infeed and outfeed of the HEUFT InLine II IR for higher line outputs and even more precision. Each empty bottle is purposefully rotated between the individual detection stations so that it can be continuously examined from all sides. Blind spots in the detection pictures put together by the HEUFT reflexx² are therefore ruled out.

Fullscreen

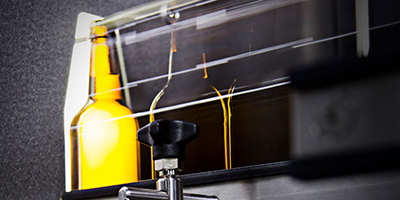

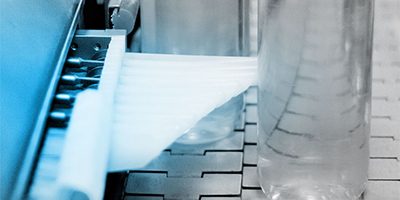

Residual liquid detection

Tracking down lye, oil and varnish: effective protection against product contamination.

Caustic lye, oil or varnish: even minute amounts of residual liquid seriously threaten the safety of the end product. The system has two different methods in order to detect and remove the empty bottles in question before the filling process: it identifies residual lye using high frequency technology (HF) and oil and varnish with infrared technology (IR). The IR detection, safely enclosed, is directly integrated in the compact device together with its own LED illumination panel. The HEUFT fluid module for the reliable detection of health hazardous lye remains can be installed easily and using little space directly on the bottle conveyor. The entry-level device for inspecting empty bottles therefore provides effective protection against product contamination due to harmful residual liquid.

Fullscreen

Espulsione dei contenitori difettosi

Prevenire i richiami di prodotto: espulsione affidabile dei contenitori difettosi.

Veloce, attenta e accurata: la più alta precisione nel rilevare i difetti è realmente efficace solo se i prodotti difettosi vengono rimossi subito dopo. I sistemi di espulsione a segmento singolo o a multi-segmento della famiglia HEUFT svolgono questo compito con precisione e attenzione.

Fullscreen

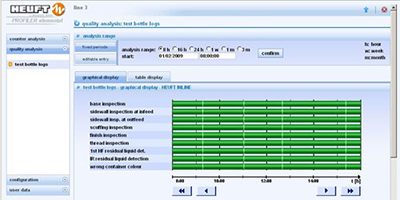

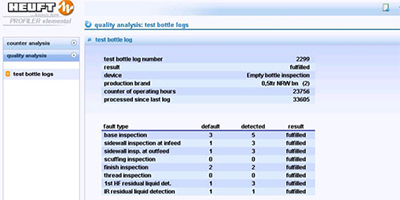

Monitoraggio del prodotto e auto-test

Andare sul sicuro: tracciare esattamente il prodotto ed eseguire test di funzionamento a scadenza regolare.

Conoscere sempre la posizione esatta di ogni prodotto grazie a un sistema molto preciso di tracciamento. Questo assicura che nessun contenitore venga trascurato dall’ispezione.

Leggi di più...

La verifica integrata di avvenuto scarto controlla che ogni prodotto classificato come difettoso venga effettivamente deviato dal flusso produttivo. Programmi automatici di test assicurano un controllo periodico delle prestazioni di rilevamento. E’ possibile inoltre il monitoraggio continuo tramite rete Ethernet e l’archiviazione a lungo termine dei risultati.

Fullscreen

Optional additional functions

Detecting even more: extensions to the range of functions.

The HEUFT SPECTRUM II systems with their modular design can be expanded at any time. Thus the optionally available colour ring inspection provides even more detection accuracy during the finish inspection. Even thermal cracks and extremely fine tension cracks in the sealing surface can be reliably detected with it. In addition a special optical technology for the precise inspection of the inside of the finish can be integrated upon request. Whether single, double or quadruple sidewall inspection: there are various options available depending on the performance range and quality requirements. Even a module for examining the inner bottle walls can be integrated without a problem. A special scuffing detection for the HEUFT InLine II IR is also available for those filling into returnable bottles.

HEUFT SPECTRUM II

Automazione totale: unità di controllo universale per prestazioni ancora più elevate.

Completamente automatica, potente e universale: la famiglia elettronica HEUFT SPECTRUM II assicura la massima affidabilità di rilevamento durante l’ispezione e garantisce la qualità del prodotto e l’efficienza della linea produttiva. Essa è adatta per lavorare con moduli, sistemi e applicazioni diversi e convince grazie al suo elevato grado di automazione.

Leggi di più...

Permette di eseguire cambi formato totalmente automatici, senza alcun intervento manuale. L’interfaccia utente è autoesplicativa e risulta assolutamente intuitiva. In questo modo si attua un grosso risparmio per quanto riguarda le risorse umane. Hardware e software di ultima generazione sono stati sviluppati da HEUFT, mentre connessioni di rete all’avanguardia assicurano la massima potenza di calcolo e di velocità nella trasmissione dati in tempo reale. Il risultato: massima precisione durante il tracciamento, l’ispezione e l’espulsione del prodotto.

Fullscreen

HEUFT reflexx A.I.

Rilevare ancora di più: elaborazione di immagini in tempo reale con l'intelligenza artificiale.

La disciplina AI dell'apprendimento automatico per la classificazione mirata degli oggetti è stata padroneggiata dalla nostra elaborazione di immagini sviluppata in proprio a partire dal 2010! E da allora ha imparato molto: i filtri intelligenti distinguono le gocce d'acqua sul contenitore dalle bolle d'aria nel vetro e permettono persino di identificare piccoli difetti nascosti dietro ACL o rilievi. HEUFT reflexx A.I. ora utilizza anche il deep learning!

Leggi di più...

Le reti neurali opportunamente addestrate vengono utilizzate, ad esempio, per il denoising di immagini a raggi X o per individuare oggetti estranei pericolosi in prodotti strutturati e distinguerli in modo affidabile da oggetti buoni estremamente simili per forma, dimensioni e densità. Grazie a una vera e propria intelligenza artificiale, l'hardware e il software sviluppati e prodotti in proprio aumentano nuovamente l'affidabilità del rilevamento e riducono al minimo il tasso di falsi rifiuti. L'elaborazione intelligente delle immagini può essere integrata direttamente nella telecamera HEUFT reflexx A.I. sviluppata internamente, che elabora e valuta le proprie immagini direttamente in tempo reale e porta l'analisi adattiva delle immagini a un livello superiore.

Fullscreen

HEUFT NaVi

Sapere sempre cosa fare: la guida utente audiovisiva e autoesplicativa.

Intuitiva, audiovisiva e adatta a tutti: non è richiesta alcuna conoscenza precedente per poter lavorare con affidabilità con i sistemi HEUFT SPECTRUM II. L’interfaccia HEUFT NaVi è autoesplicativa e guida l’utente passo per passo.

Leggi di più...

Un sistema di login RFID fornisce accessi riservati per ciascun utente e semplifica decisamente il loro rispettivo lavoro: ogni utente vede solo quello che deve vedere grazie ad un’interfaccia pienamente configurabile, visibile su pannello “touch-screen” e dotata di menù dalla struttura semplice, tutorial integrati e strumenti ausiliari che possono aiutare l’operatore nello svolgimento ottimale dei suoi compiti. Viene in aiuto anche un’assistente virtuale, la quale parla all’utente e gli spiega dove, come e quando intervenire. Concentrata sullo scopo finale e sugli aspetti essenziali – l’interfaccia utente audiovisiva HEUFT NaVi rende il lavoro con i sistemi HEUFT affidabile ed estremamente semplice!

Fullscreen

HEUFT checkPoints

Simply seeing where what has to be done: trouble-free localisation.

Clear, direct and purposeful: the user can cope immediately on the rare occasions when manual intervention is needed. Because eye-catching HEUFT checkPoints make it clear at a glance exactly when it is necessary to take matters in hand in addition to the audiovisual information which the HEUFT NaVi provides.

read more...

The orange tags with clearly assignable letters are on the device components where intervention may be required. If the worst comes to the worst the HEUFT NaVi shows them on the touchscreen. The HEUFT checkPoints then even optionally flash on the respective component in each case. The problem is located without a long search. This saves time and human resources, shortens standstills and therefore increases productivity.

Tecnologie di rete

Tutto in rete: essere “online” per far crescere efficienza e qualità.

Trasmissione di informazioni in tempo reale, acquisizione dei dati di produzione, analisi della linea e manutenzione da remoto: la rete è la risposta!

Leggi di più...

I sistemi HEUFT sono dotati di interfacce all’avanguardia di rete (Gigabit Ethernet e TCP / IP) e di database (SQL / DDE) per la massima efficienza della linea e del controllo qualità, con flussi di lavoro più veloci e semplificati. Pertanto dati di produzione, registri degli accessi, difetti di produttività e analisi dei valori HACCP sono disponibili online. Il risultato di tutto questo è una precoce identificazione dei problemi. La connessione ai servizi di HEUFT TeleService è protetta da firewall e garantisce l’assistenza remota 24 ore su 24.

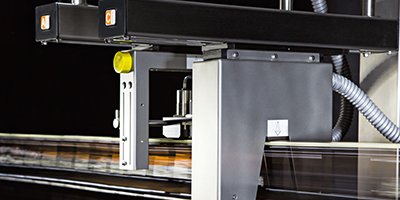

HEUFT CleanDesign

Pulire con facilità: costruzione ottimizzata per l’igiene.

Accessibile, pulito e sicuro: il sistema HEUFT CleanDesign rende possibile l’uso dei dispositivi HEUFT in aree sensibili dal punto di vista igienico. Superfici inclinate facilitano la pulizia e prevengono l’accumulo di sporco.

Leggi di più...

Speciali canali e aperture permettono ai liquidi necessari per la pulizia di essere drenati completamente. Di conseguenza i germi e i batteri hanno poche superfici utili di contatto. Speciali alloggi e aperture garantiscono un’ottimale accessibilità. Le parti elettroniche sono totalmente protette. Le aree sensibili, quali i moduli ispettivi, sono a prova di polvere e protette contro spruzzi e getti d’acqua.

Fullscreen

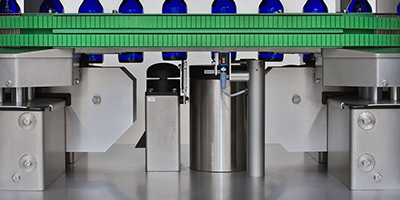

HEUFT rejector

Removing faulty products: the right rejector for all cases.

For example, the single-segment HEUFT mono rejector as well as the multi-segment HEUFT DELTA-FW and HEUFT DELTA-K systems are ideally suited for the reliable rejection of faulty empty bottles. A total of up to four rejection systems can be connected to the HEUFT InLine II IR. This also makes a rejection possible which is sorted according to the fault type.

- high-tech for all – extremely compact, affordably priced system for the continuous complete inspection of empty bottles on a HEUFT SPECTRUM II level

- proven design features and detection technologies combined with the performance of the new generation

- significant increase in automation, computing and detection power

- audiovisual HEUFT NaVi user guidance and HEUFT checkPoints for an easy, tamper resistant operation

- high detection accuracy and low false rejection rate

- space-saving construction (one square metre of floor space) in accordance with the hygiene-optimised HEUFT CleanDesign

- flexible modules, equipment and configuration options for small and large demands, performance ranges and installation positions – ideal for SMEs