Unclouded enjoyment of champagne!

High-performance inspection solutions from HEUFT not only ensure the quality and integrity of champagne bottles but also the clarity of their noble contents.

HEUFT has installed innovative inspection solutions at a major producer so that enjoyment of champagne also remains unclouded in terms of packaging and product quality – one for a finish inspection of the filled champagne bottles immediately after "disgorging" and one after the final corking for a turbidity detection and an all-around closure inspection.

This is because the second fermentation takes place in the bottle during the production method also known as "méthode traditionelle" which is what makes champagne champagne in the first place. Leftover residual yeast settles in the neck of the bottle directly below the finish which is sealed with a simple crown cork first during the subsequent "remuage" – the typical shaking. And this can become damaged during the

so-called "dégorgement" if the yeast deposit freezes into a plug and shoots out of the bottle when the crown cork is opened.

Finish crack and turbidity detection

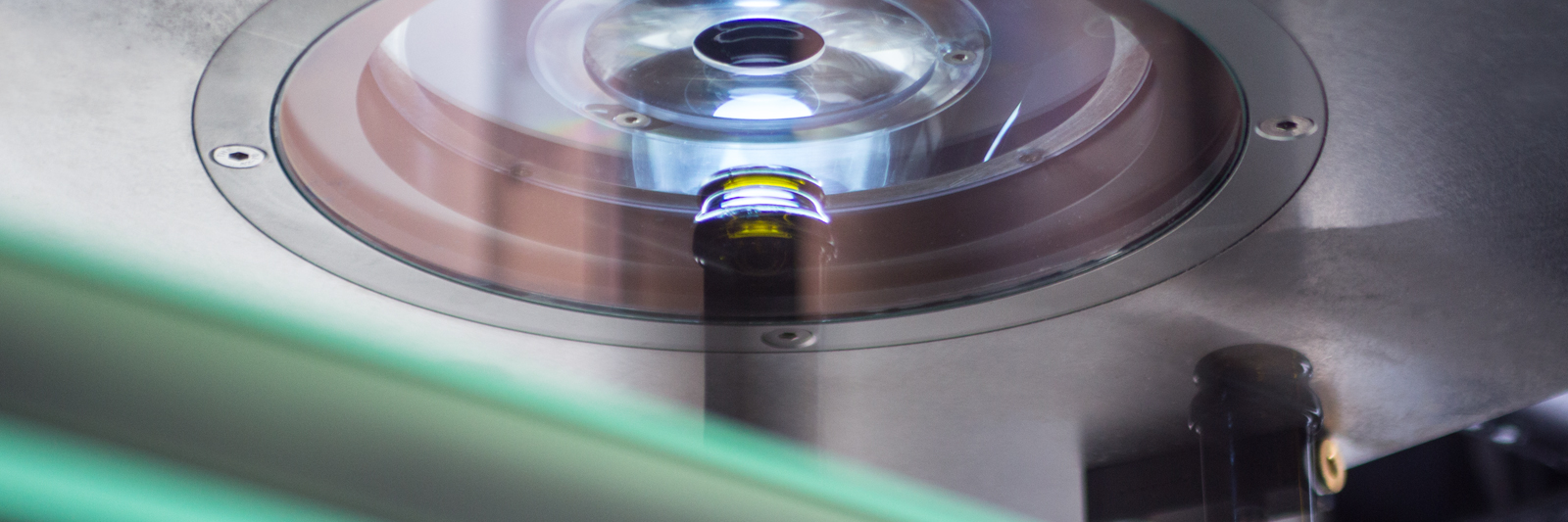

Above all chips can occur at the finish sealing surface which impair the integrity of the container and the safety of the product inside severely. The proven module for a colour finish inspection identifies these connected to a HEUFT SPECTRUM II VX fill management system and not, as usual, to a HEUFT InLine II empty bottle inspector. In addition even the smallest defects inside and damaged neck rings below the finish can be reliably detected.

Above all chips can occur at the finish sealing surface which impair the integrity of the container and the safety of the product inside severely. The proven module for a colour finish inspection identifies these connected to a HEUFT SPECTRUM II VX fill management system and not, as usual, to a HEUFT InLine II empty bottle inspector. In addition even the smallest defects inside and damaged neck rings below the finish can be reliably detected.

A sophisticated combination of HEUFT FinalView II CAP and HEUFT floater optics uncovers deviations in the colour of the champagne and even unwanted product cloudiness after the final corking. For example the latter can occur if the yeast has not been removed from the bottle entirely during "dégorgement". A background with alternating transparent and black stripes has simply been placed behind the bottles to be examined in order to be able to detect them reliably. These stripes then become blurred on the detection image during the colour camera based sidewall inspection if the champagne inside is not as clear and pure as it should be.

Complete cork, capsule and agrafe inspection

In addition this optical all-around inspection of the top of the bottle checks the integrity and safety of all the closure elements before the full product is stored in the cellar again for a few months to mature. Corks which are too high, too low or broken are detected just as reliably as faulty or incorrectly positioned capsules and brackets as well as improperly flanged, misshapen or incomplete wire cages (agrafes) which in the worst case can cause the cork to pop prematurely. After all this should only happen shortly before the consumer wishes to make a toast and not during storage, transport or on the retail shelves.

In addition this optical all-around inspection of the top of the bottle checks the integrity and safety of all the closure elements before the full product is stored in the cellar again for a few months to mature. Corks which are too high, too low or broken are detected just as reliably as faulty or incorrectly positioned capsules and brackets as well as improperly flanged, misshapen or incomplete wire cages (agrafes) which in the worst case can cause the cork to pop prematurely. After all this should only happen shortly before the consumer wishes to make a toast and not during storage, transport or on the retail shelves.

This ensures the unclouded enjoyment of the most festive of beverages sustainably together with high-performance HEUFT systems for an all-surface empty bottle inspection and reliable glass in glass detection in full containers.