Line analysis made easy!

Like almost all our hardware and software products developed, manufactured and programmed in-house, our IT tool for production data acquisition (PDA) and line analysis has recently been given a new name: HEUFT CyBridge.profiler! The latest innovations in terms of functionality, modularity, usability and design make it easier to sustainably ensure the efficiency and production quality of complete filling and packaging lines.

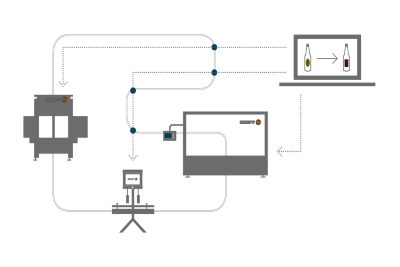

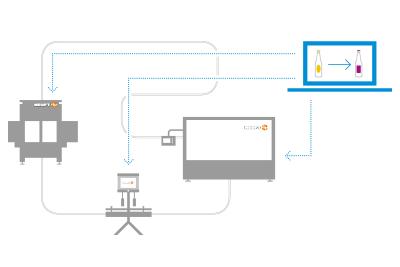

It builds a bridge to the digital world and records operating and quality data in real-time. For example, as a lean software solution it automatically logs regular test container programmes which the HEUFT inspection systems use to check their own detection performance. With the new HEUFT CyBridge.profiler comprehensive PDA and line analysis including key figures of HEUFT devices and machines of other manufacturers is possible via the HEUFT CyBridge.hub server platform which is available in two variants: a rack version and a virtual version for integration into an existing server environment.

The HEUFT CyBridge.profiler can be networked not only with HEUFT devices but also with all other machines in the filling line. The people responsible for efficiency and quality management there can thus obtain an up-to-date overview of their status at any time. The new clear interface with attractively presented key figures, messages, statistics, diagrams and graphics can now be displayed accurately and vividly on all common web browsers and mobile devices such as tablets and smartphones. HEUFT CyBridge.profiler users decide for themselves how consumption meters or HACCP data, for example, are best displayed on it in order to monitor and evaluate the performance of individual devices, the overall equipment effectiveness (OEE) and the overall production quality.

Comprehensive production data acquisition, individual analyses

The further developed PDA tool calculates all the relevant key figures in accordance with the specifications of the Weihenstephan Standards which HEUFT helped to develop as an industrial partner and processes them individually in an OMAC-compliant way. Different counters can be displayed in one and the same diagram in order to compare the number of containers checked in the in-line inspection with the number of containers rejected afterwards, for example. Weak points and faults are revealed directly in this way. Their causes can then already be eliminated before the efficiency of entire lines suffers. Unplanned stoppages are completely avoided or at least reduced considerably.

From the logic to the buffer analysis, from the downtime monitoring to the batch report and the audit trail protocol relevant for pharmaceutical producers: the HEUFT CyBridge.profiler can now be tailored even more precisely to the specific needs of the respective bottler and the individual requirements of the responsible line manager due to its modular design – and additional functions and features can be added to it later if required. The complete line visualisation with real-time status and event displays and the backup of the configuration data and logbook entries of all connected devices in a new central archive for simple resets are also new.

Permanent monitoring, professional reporting

The HEUFT CyBridge.profiler generates professional records for the comprehensive reporting of important key figures which can be printed out at any time, sent electronically and archived for a long time in order to fulfil basic documentation requirements. Such a report then contains clearly illustrated infographics for analysing line efficiency which compare the net operating time of individual machines with the total operating time of the respective line.

As already mentioned this applies to HEUFT control units, inspection systems and labellers as well as to machines from other suppliers. Even their digital and analogue signals can be included in the analysis so that for example an exact monitoring of the caustic temperature of the bottle washer or the downtime of the filling machine is possible. Important key performance indicators can be selected, defined and calculated freely in order to generate very specific analyses and reports as well.

System technology 4.0

The necessary inspection quality is ensured by logging of the self-test programmes of HEUFT inspectors, the monitoring of HACCP limit values and also the newly integrated module for recipe and type monitoring – an ideal addition to the also newly renamed HEUFT Cybrigde.reciper, which realises a complete recipe management and central brand changeover.

Thanks to brand new features, even more modularity and flexibility, a tidy, modern design and optimised usability it is now simply easier to achieve even more with both further developed IT tools from HEUFT when it comes to sustainably maintaining the efficiency, productivity and production quality of complete filling and packaging lines at a high level. They build a secure bridge to the digital world with innovative system technology 4.0.