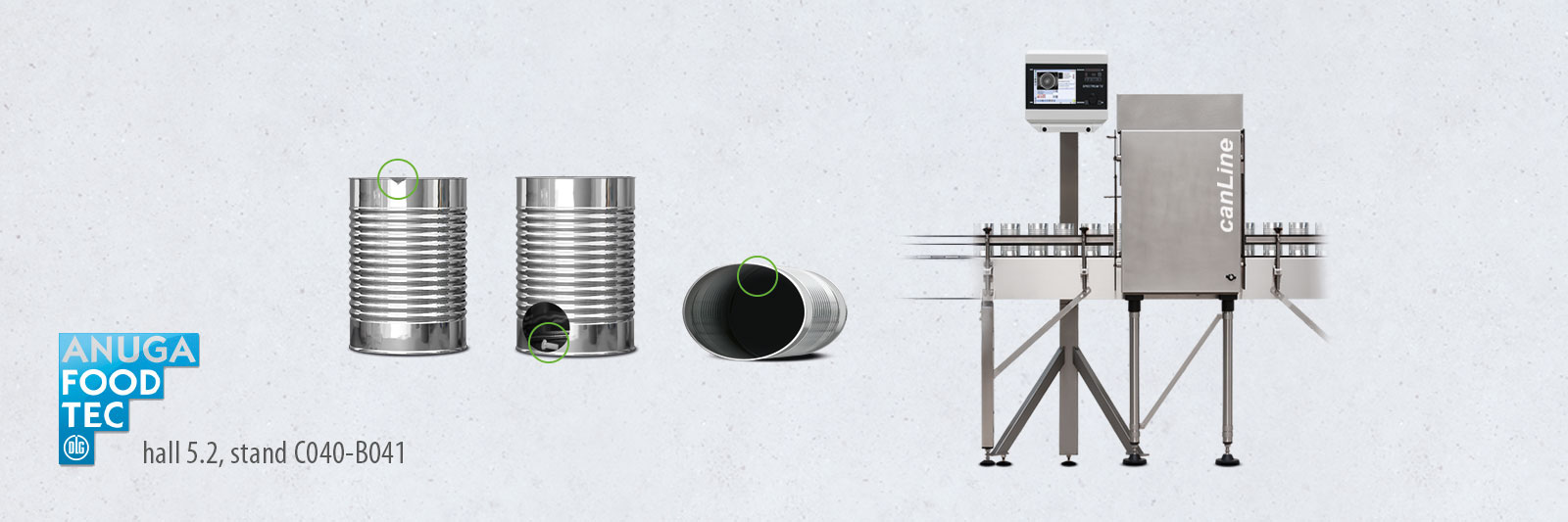

Safe preserves at high productivity

Its proven performance along high-speed beverage lines also predestines it for the inspection of empty food cans: the compact HEUFT canLine prevents productivity losses due to closer obstructions caused by deformed packaging material, safeguards their hermetic sealability and detects foreign matter and contamination even in areas which are difficult to examine. A device version especially for canners can soon be experienced live: at Anuga FoodTec 2018 in Cologne, Germany.

The top-down inspector reaches true peak values regarding depth of field with only one high-performance camera and superior real-time picture evaluation: the HEUFT canLine finds deformed finish areas as well as defects and indentations at the flanged edge just as reliably as foreign objects on the base, dents in the can body and even inconspicuous contamination in the crimps and welded seams of each individual piece of packaging material. And that even in the absolute high-speed section of up to 2,400 empty cans per minute.

The device sorts out all those which cannot be safely filled or sealed before line stoppages can occur due to closer obstructions, closure leaks and additional risks to the purity, safety and quality of the end product. A new version of the compact inspector especially for empty food cans will be shown in action at Anuga FoodTec – from 20 to 23 March 2018 on Stand C040-B041 in Hall 05.2 at the Cologne Exhibition Centre.